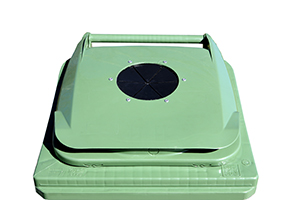

C120 F

Quality, functionality and ergonomics

120 L

Capacity

48 Kg

Nominal load

2 Wheels

200 mm

Strong, functional and adapted to every requirement

The C120 F rear-loading container is manufactured from injection-moulded, self-coloured high-density polyethylene, stabilised against the combined effects of UV rays and water. It is produced using environmentally-friendly, recyclable materials and there are no heavy metals in the pigments used for manufacture.

The C120 F container is perfect for a range of selective collection requirements, such as paper, glass, packaging and organic matter, and can be manufactured with DIN or AFNOR collection systems.

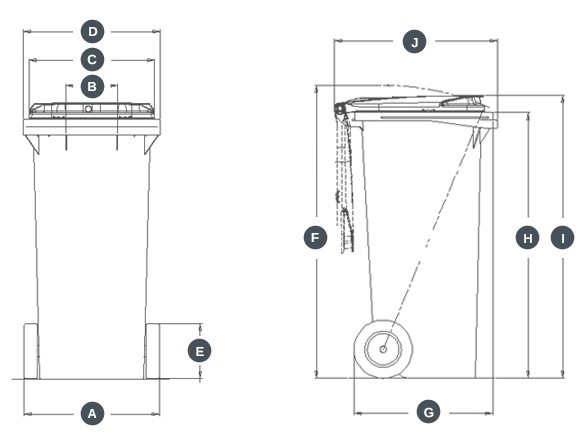

TECHNICAL SPECIFICATIONS

- A > 476 mm

- B > 183 mm

- C > 437 mm

- D > 483 mm

- E > 200 mm

- F > 963 mm

- G > 474 mm

- H > 860 mm

- I > 926 mm

- J > 552 mm

CAPACITY

120 l

NOMINAL LOAD

48 kg

Customisation

Equipment for all needs

Available in variety of colours

CONTENUR products can be supplied on order in a wide variety of colours. The high-density mass-coloured polyethylene injection system is stabilised against the combined action of water and Ultra Violet rays.

The high-density polyethylene enables the product to easily withstand the elements and makes it extremely stable when faced with temperature changes. Recyclable materials that do not have a negative environmental impact are used, as well as pigments that do not contain heavy metals, which means that the colours remain inalterable.

Download Color Chart